The History of Wheat and Flour Milling

Archeologists date the first tools of ancient man as early as 250,000 years ago. Hand axes, stone knives and bludgeons were used in hunting food and for protection. But it was only 10 or 15 thousand years ago that man began to turn his tool-making skill to the production of agricultural implements. His transition from hunting food to raising food marked the beginnings of civilization. Within a few thousand years, larger urban centers of culture known as cities came into existence.

The collection of food, wheat and other grains offered man a number of advantages. Grains could be stored without spoiling. They could be stocked or carried from place to place and prepared in any number of ways. Grain could be traded for other essentials or comforts, eventually leading to the development of commerce and a means of supplying food for city populations from distant fields.

Planting, Reaping & Threshing

Planting

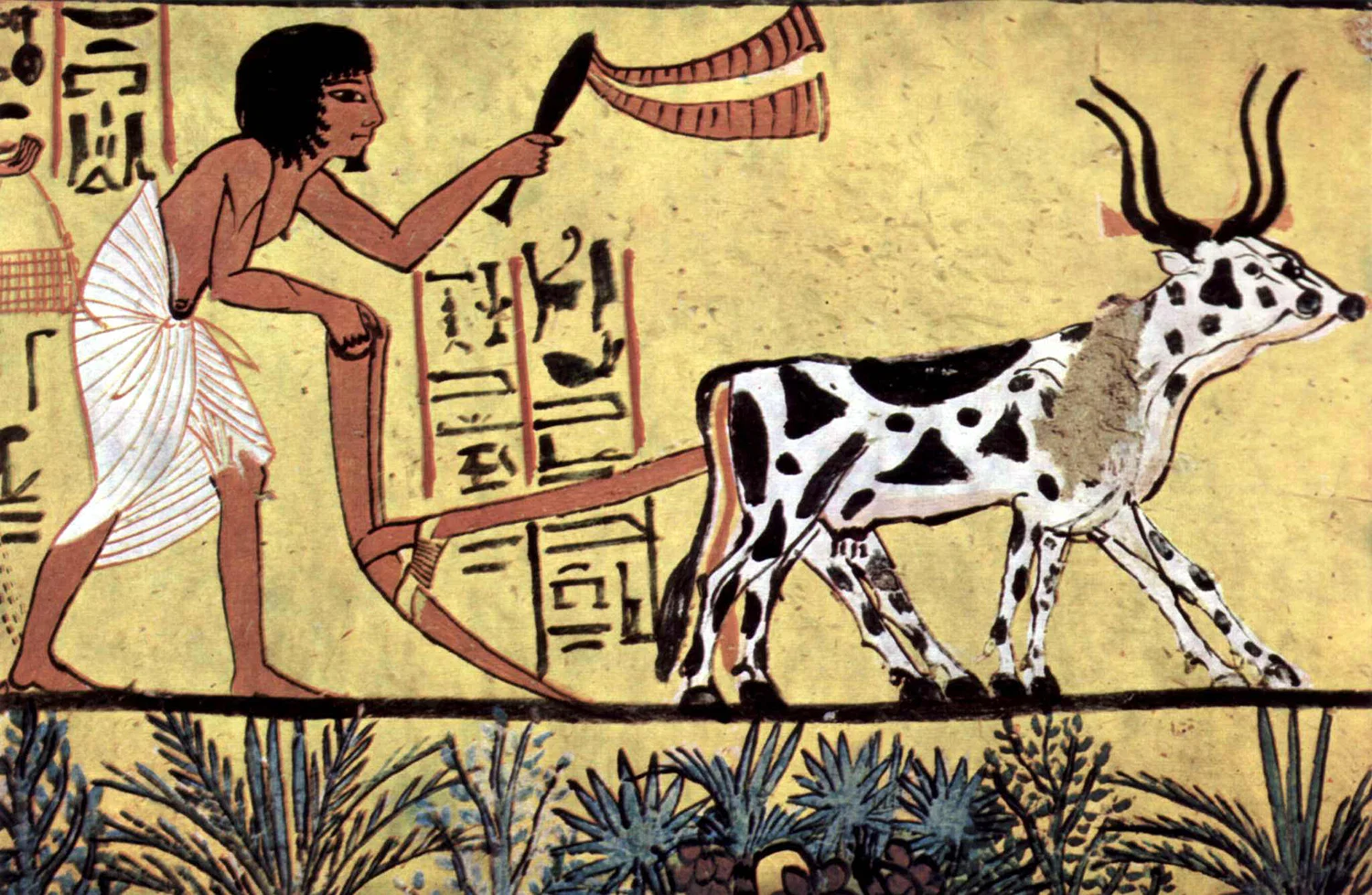

The first step in planting grain is breaking up the soil so that the seed may be covered. The most primitive instrument for this probably was a sharp digging stick or a sharp stone lashed to a handle. Egyptian drawings show the use of a triangular tool made by hinging two sticks at one end. The longer stick served as a handle and the shorter as a blade, swung with a chopping or hoeing action. A hoe of this type dating from 1,000 B.C. has been found intact. Other Egyptian drawings from 2,500 B.C. show such a hoe-like instrument or plow equipped with a pair of handles, drawn by oxen. A similar, one- handled-plow with a single point, dating from 300 B.C. was found in Denmark. In many parts of the world today, farmers use implements almost as crude and primitive.

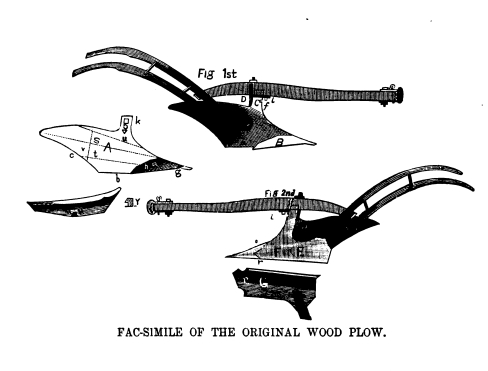

Great changes in the agricultural revolution came with the development of iron and steel and are today scarcely 160 years old. In 1819, a New York State farmer, Jethro Wood, patented a cast iron plow. Iron was soon replaced by steel, and a series of plowshares were attached to a single frame in an implement called a gang plow. With his tractor, today’s farmer pulls a series of steel points fitted to a single frame to help pulverize the soil after plowing. This implement is called a spike harrow and is used to reduce the soil to smaller fragments. Soil kept pulverized and free from weeds retains moisture needed by the seeds and wheat plant.

To sow seeds into soil ancient Egyptians cast seed wheat directly into the mud left by the retreat of annual floodwaters along the Nile. Cattle were driven over the area to trample the seed into the ground. For thousands of years, a more common method of sowing seed has been the broadcasting of wheat – scattering it evenly by hand- a procedure still used today in many parts of the world. Working in this fashion, with a sack of grain slung over his shoulder, it would take a skilled man about 90 minutes to sow just one acre of wheat.

The modern farmer seeds his field with a machine called a drill. Seed for planting is contained in a hopper at the top, from which the seed is funneled evenly down into the earth and covered lightly with soil.

World History Encyclopedia - Plowing Egyptian Farmer

World History Encyclopedia - Plowing Egyptian Farmer Wikipedia Image - John Wood Moldboard

Wikipedia Image - John Wood Moldboard

Reaping

As in planting, instruments used to harvest wheat evolved during ancient times from the first sharp stones fitted into a wood or bone handle into skillfully crafted cutting instruments. The adaptation of iron and steel helped man develop the sickle, a balanced tool that was easy to swing. Even after 4,000 years sickles are still widely used. They are light enough for work by women and children. They permit the cutting of wheat at any height, so that the straw can be left standing or cut separately. The importance of the sickle in the history of man reaches a point of symbolism – perpetuated in the Russian hammer and sickle device, and in many works of art.

An improvement over the sickle was the scythe- a longer blade with only a slight curve, fastened at right angles to a long wooden handle. Wheat could be cut faster with a scythe, and the worker could stand upright. But the straw had to be cut close to the ground, leaving it attached to the wheat head. A scythe is also a heavier instrument that requires a strong man for prolonged use.

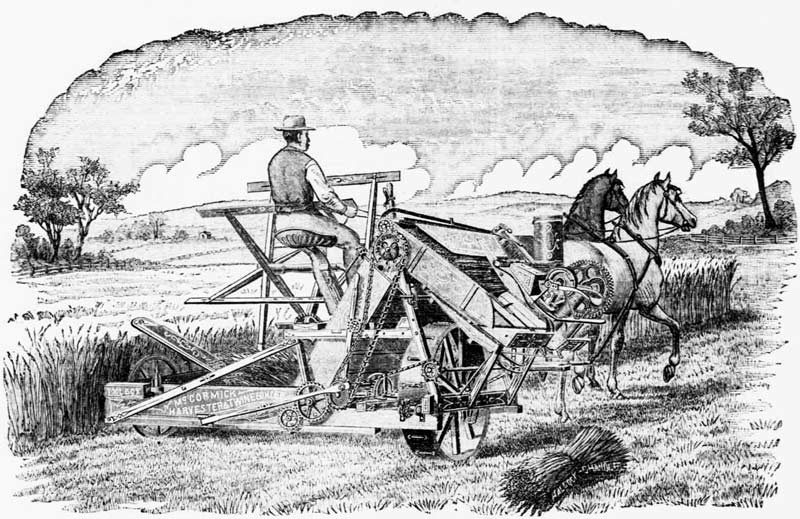

As the wooden plow was displaced by iron and steel, better and more efficient methods of cutting were developed. In 1831 Cyrus McCormick invented a mechanical reaper. The two wheeled, horse-drawn invention pushed a series of moving, scissor-like blades against the grain to clip if close to the ground. A rotating paddle wheel swept the stalks against the cutting bales so they fell on a platform as the machine moved forward.

Seshat - Ancient Egyptian farmers harvest crops using a sickle

Seshat - Ancient Egyptian farmers harvest crops using a sickle Wikipedia - McCormick reaper and twine binder in 1884

Wikipedia - McCormick reaper and twine binder in 1884Threshing

The modern farmer usually takes a sample of wheat to a local elevator for testing to check moisture content, which determines whether or not it is ready to harvest and can be stored. Wheat is relatively hard and dry when ripe. At this time, the crop is also an easy target for destructive fire, wind, rain or hail during a critical week to 10-day period when the grain must be cut.

A number of methods can be used to thresh out the cut grain and remove the wheat from its glumes. For thousands of years, wheat heads were spread on a plot of bare, hard ground or threshing floor. Cattle or horses were driven around and around until hooves accomplished the removal of the wheat from the chaff. Separation was completed by winnowing-or tossing the mixture into the air so that the wind blew away the lighter chaff and the heavier wheat dropped back.

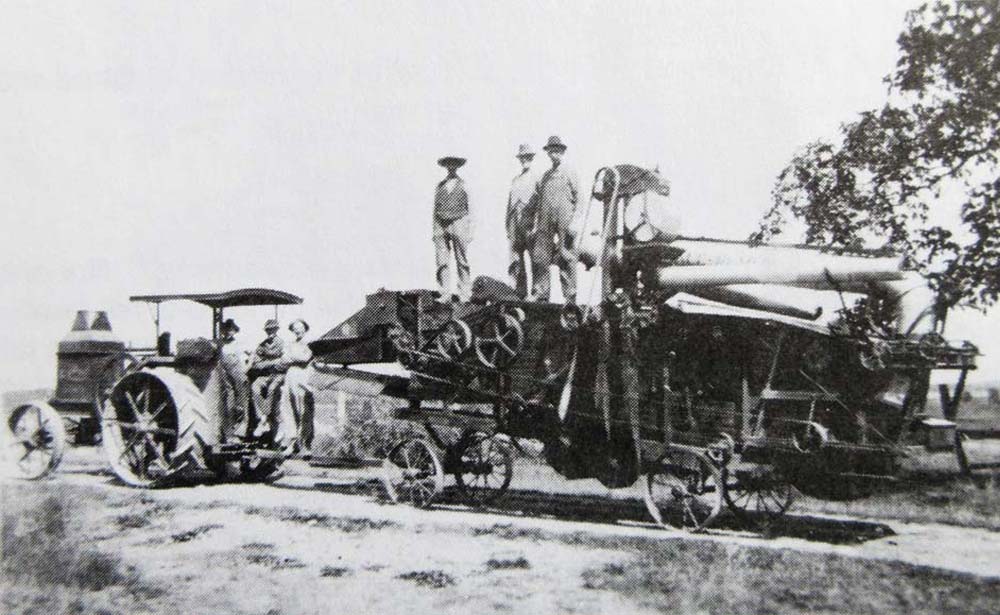

The mechanical ingenuity that led to the development of a reaper also led to the development of the threshing machine. Industrialization- the use of new sources of power in steam and internal combustion engines, the improvement of transportation, and the growth of cities with greater need for food- served to revolutionize agriculture. During the 19th and early 20th centuries, the time required for cultivation and complete harvest of one acre of wheat declined from an estimated 83 hours to little more than two man-hours. The invention of several machines made this saving possible.

One of the inventions, the threshing machine, used power fans to separate the chaff from the grain. The machines were expensive and often purchased by companies of farmers or independent businessmen. Local groups called “threshing rings” were formed of ten to twenty-five growers, and the farmers would cut and shock the grain in the fields belonging to members. The shocked grain was hauled in from the field and fed into the threshing machine. Chaff and straw were blown out into the pile on one side. Clean grain poured into a wagon or bags on the other side. The “threshing rings” also hired itinerant workers from the cities. This annual migration of thousands of harvest hands came to an end after the end of the First World War with the development of the combine, first as a unit to be drawn by horse or tractor and finally self propelled.

The modern combine, in one operation, performs the five basic jobs in harvesting once done by hand labor:

-

- Cutting – replaces the sickle, scythe or cradle

- Feeding – eliminates hauling the cut or bunched stalks of wheat

- Threshing – formerly accomplished by flail or some other method of extracting the whole grain from its hull

- Separating – tedious discarding of stalks

- Cleaning – separating the wheat berry from all other particles

The combine reduced the man hours of work of harvesting one acre of wheat from 46 hours to 30 minutes or less and freed thousands of men for productive work outside the farm.

Wikimedia - Threshing harvest Sangrur Punjab India

Wikimedia - Threshing harvest Sangrur Punjab India Farmington Historical Society - Mueller Road threshing crew with Landvatter's steam-powered thresher, circa 1900

Farmington Historical Society - Mueller Road threshing crew with Landvatter's steam-powered thresher, circa 1900

Early Milling

Wheat has been processed for centuries to separate its outer bran and germ from the inner, more digestible, endosperm. Initially, ancient people likely chewed wheat or parched it for easier consumption. However, evidence from excavated villages dating back to 6,700 BC shows they were already using stones for milling wheat. The use of pairs of stones for pounding or rubbing grain effectively produced flour or meal.

The wearing action from rubbing stones together created depressions, leading to the evolution of simple mills. The ancient Egyptians used saddlestones and mixed their sifted flour with natural yeast to make various types of leavened bread, as seen in murals in Tombs along the Nile River.

Over time, levers were added to millstones to increase grinding power. The “hourglass mill,” a Grecian invention, extended the top stone to create a grain hopper. Flour production remained based on similar principles for millennia, powered by humans, animals, water, or wind.

Later, the application of wind or waterpower enabled larger mills and increased flour output for larger markets. The Romans are believed to have been the first to use waterpower for milling flour, about 100 B.C.

19th Century Milling

In the 19th century, industrial development led to significant advancements in milling practices, reflecting the era’s technological progress. Power from shafts, belts, and gears facilitated the turning of milling stones, and water emerged as a more reliable power source than wind, leading to the construction of larger milling plants near waterpower sources.

Oliver Evans, an American millwright, introduced innovative machines such as screw conveyors and bucket elevators, creating the first continuous milling system. These machines, combined with sifters, allowed wheat to be milled into flour without interruption, resulting in purer flour due to added cleaning mechanisms.

The adoption of industrial techniques and reliance on water power, along with improved transportation and westward expansion, shifted milling centers from the East to the Midwest. The use of harder wheat and the “New Process” method encouraged the gradual separation of wheat into bran and white flour, achieving high extraction rates.

Roller mills replaced traditional grindstones, offering various advantages, including better-grade flour, increased efficiency, and the ability to handle harder bread wheats. Steam engines, like the one invented by James Watt, further revolutionized milling, providing new power sources and freeing millers from natural power dependencies.

19th century waterpower grain mill

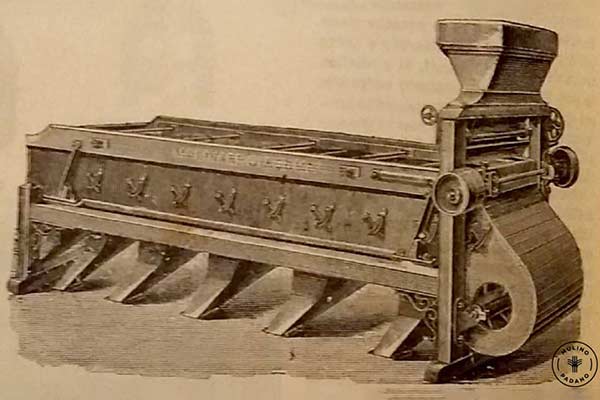

19th century waterpower grain mill Wikipedia - A late 19th century double roller mill

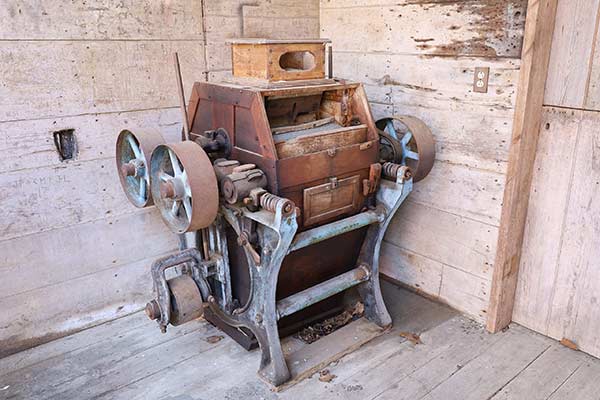

Wikipedia - A late 19th century double roller mill  Mulinopadano - Example of a Marseillaise cleaner

Mulinopadano - Example of a Marseillaise cleanerThe use of rollers for milling, initially developed in Europe, made its way to America, and an all-roller mill was briefly operated in Philadelphia in 1876. Roller mills eliminated the cost of dressing millstones, allowed for longer and more gradual extraction, and contributed to the construction of larger and more efficient mills.

The middlings purifier, invented by Edmund La Croix, significantly improved flour yield and quality. By breaking up the wheat endosperm into bran-free granular “middlings,” the milling process could produce higher-grade flour. Air currents and bolting cloth were combined in La Croix’s system to efficiently separate bran from middlings, contributing to continuous improvements in flour milling.

The second half of the 19th century witnessed remarkable developments in flour milling, with numerous patents issued for mechanical advancements in the milling process. These improvements, aimed at separating the outer bran and germ from the floury endosperm, culminated in the establishment of modern mills, capable of meeting the demands of a growing nation.

20th Century Milling

Wheat arrives at modern mills and elevators by ship, barge, rail or truck. Chemists in product control, who inspect and classify grain, take samples of each shipment. A small quantity is milled into flour. The character of the wheat itself, it’s milling and baking qualities, determine how it is handled. Different wheats are usually blended before milling to achieve the desired end product. Similarly, different types of flour are blended to customer specifications and to provide desired baking characteristics.

The average bushel of wheat weighs about 60 pounds. At the standard extraction rate, providing about 72 percent flour and 28 percent mill feed, approximately 2.3 bushels of wheat are required to produce 100 pounds of flour.

A simplified schematic flow chart of 20th century milling is available by selecting the How Flour is Milled link. The flow chart displays the elementary steps in processing wheat into flour and explains the use and value of each separate machine. It is quite probable, however, that no two flour mills will ever be quite alike in terms of an exact sequence, placement or identity of machinery. The men who build the machinery, millwrights, constantly modify and improve the equipment according to the suggestions of technicians or the millers themselves. Equipment size, shape, source of power and daily capacity all serve to individualize each flour mill.